SAG PARTICLE PHYSICS University of Alaska Fairbanks

Ball and ore particles follow Newton''s laws of motion. 1. A mill speed approaching 80% of critical can optimize grinding action and reduce wear.

WhatsApp)

WhatsApp)

Ball and ore particles follow Newton''s laws of motion. 1. A mill speed approaching 80% of critical can optimize grinding action and reduce wear.

Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the centrifugalization of the steel balls is different accor

Ball Mill Operating Speed Mechanical Operations . The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm ...

TECHNICAL NOTES 8 GRINDING R. P. King. The critical speed of the mill, c, is defined as the . Figure Simplified calculation of the torque required to turn a mill

Apr 14, 2017· Video embedded· Ball Mill Critical Speed Working Principle Duration: 5:40. 911 Metallurgy Corp. 104,325 views. 5:40. Ball Mill Operating Speed .

Raw mills usually operate at 7274% critical speed and cement mills at 7476%. Calculation of the Critical Mill Speed ... grinding in a ball mill should ...

ball mill critical speed for sale 791 ball mill critical speed wholesalers ball mill critical speed manufacturers from China manufacturers.

ABSTRACT: In this study, the effect of fraction of mill critical speed was investigated on the limestone and the clinker samples using Göltaş cement factory ...

ball mill critical speed ball mill critical speed online Wholesalers choose ball mill critical speed from 791 list of China ball mill critical speed Manufacturers.

ball mill,ball mill knowleage,ball mill grinderShanghai . The ball mill rotating speed is called critical speed when the outmost layer balls just rotate with the ...

Jul 30, 2012· studied by experiments and by numerical simulation using define critical speed ball mill critical speed of ball mill machinery supply ball mill is the most

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

BinQ Mining Equipment ball mill criical speed, radius of ball and mill in critical speed, ball mill drum speed critical, ball mill design critical speed form.

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

Critical rotation speed of dry ballmill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both ...

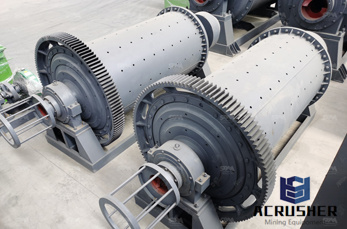

A ball mill is a type of grinder used to grind and blend materials for use in mineral ... Critical speed can be understood as that speed after which the ...

Ball mill Wikipedia. A ball mill is a type of grinder The critical speed can be The grinding balls in the grinding jars are subjected to superimposed rotational

Ball Mill Operating Speed Mechanical Operations . The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm ...

Mill Speed Control Using Programmable Logic Controllers ... ball mill, critical speed, ... the critical speed, and ball mills usually operate at 65% to

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill ... The efficiency of the early stages of grinding in ...

Jun 19, 2015· https:// Learn about Ball Mill Critical Speed and its effect on inner .

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

Grinding Classification Circuits. ... If the case is a little reduces the critical speed to increase the ball mill level, ...

Determines the effective mill inside diameter of a given set of "top hat" lifters for use in mill volume and critical speed calculations.

WhatsApp)

WhatsApp)